Check Plus Key Features

Extensive Expandability Through Customization

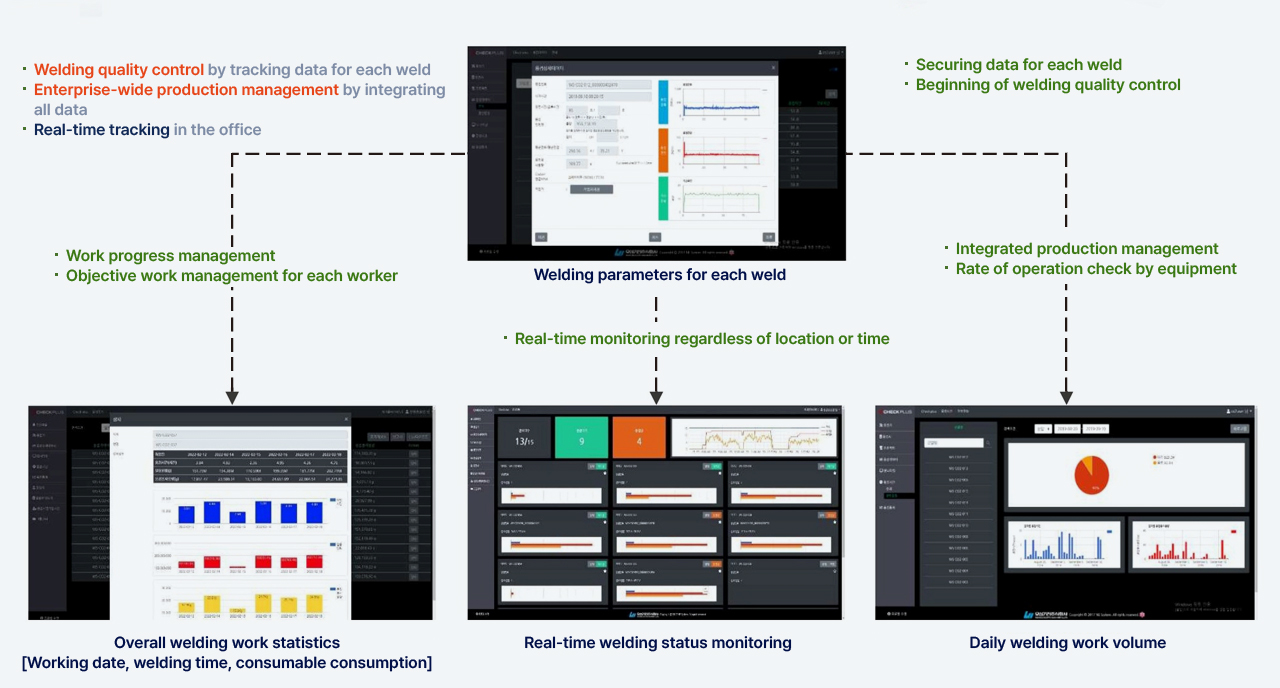

Company-Wide Welding Quality and Production Management

Roles in Quality Control

Objective Welding Quality Management Through Actual Welding Parameters

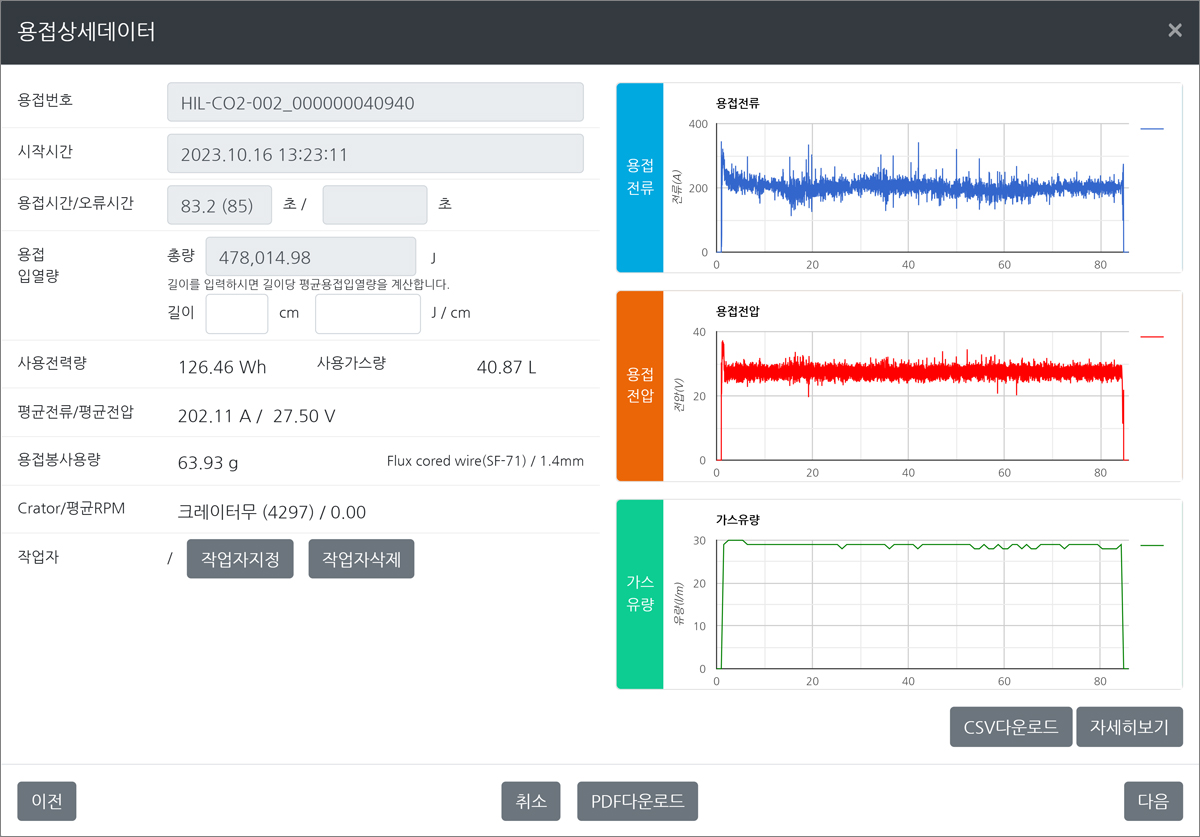

Welding Quality Control by Securing Actual Data for Each Weld

- Welding number

- Welding start time

- Welding duration

- Welding heat input

- Average welding current and voltage

- Welding graph

Comparative verification against pre-entered WPS

- Specifying and checking the current and voltage range

Step 1: Real-Time Monitoring of Welding Quality Parameters

- Function: Precisely measures and collects key quality parameters such as current, voltage, gas flow rate, and welding speed in real time during welding.

- Operating method: Sensors attached to the welding equipment read data dozens to thousands of times per second and transmit it to the system. The system immediately displays this data in the form of waveform graphs or numerical values.

- Contribution to quality: Key factors that directly affect welding quality such as arc stability, penetration depth, and bead shape are visually represented, allowing abnormal patterns to be detected immediately.

Step 2: Setting Reference Values and Detecting Deviations (In-Spec/Out-of-Spec Determination)

- Function: Sets the **optimal welding parameter reference range (min/max values)** for each welding work (by product, material, and process) and automatically determines whether the current welding parameters are outside this range.

- Operating method: The administrator enters the tolerance range for each parameter based on the Welding Procedure Specification (WPS) preset in the system or based on internal quality criteria. The system compares the data collected in real time to these criteria and determines whether it is in-spec or **out-of-spec**.

- Contribution to quality: Overcomes the limitations of visual inspection and post-process testing and effectively reduces unnecessary rework by presenting objective quality standards and detecting in advance conditions that may cause welding defects.

Step 3: Immediate Alerts and Notifications Upon Anomaly Detection

- Function: When anomalies such as deviation from predefined quality standards, arc instability, or insufficient shielding gas are detected, the system triggers visual and auditory alarms. In certain cases, remote notifications are sent to operators or managers.

- Operating method: Upon determining an “Out-of-Spec” status at the second stage or detecting a specific error code, the system activates a red warning light or emits an alert sound. When linked with automated equipment, the system can even halt the machinery automatically.

- Contribution to quality: The system prevents continued defective welds—thereby minimizing the production of defective parts—and aids in immediate recognition of and response to problems for quality improvement in real time.

Step 4: Managing Welding Data History and Generating Quality Reports

- Function: The system automatically records and manages all welding data (time, date, operator, product serial number, welding parameters, and quality assessment results) and generates various types of quality reports as needed.

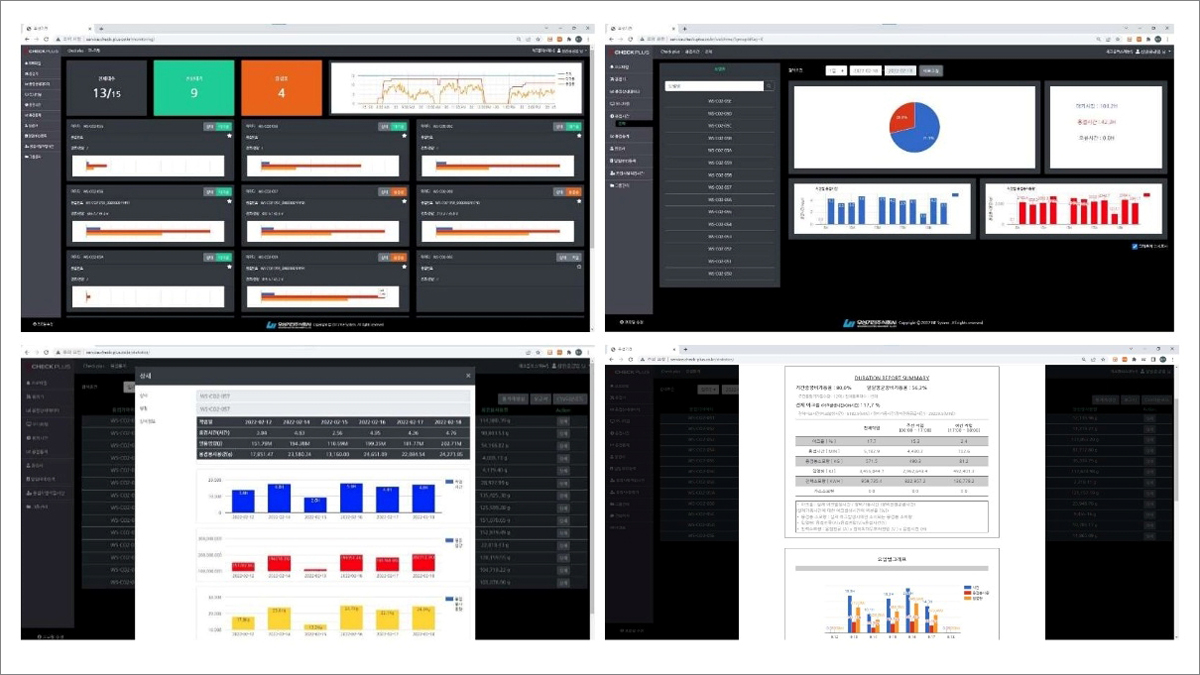

- Operating method: All welding-related data are recorded in the database either upon completion of the welding process or at predefined intervals. Users can view data by period, product, and worker and generate **statistical reports (e.g., histograms, trend graphs)** that show defect rate trends, quality improvement effects, etc.

- Contribution to quality: The system provides transparent and objective evidence of welding quality, helping meet customer requirements and supporting quality certification processes. Additionally, the accumulated data is used to analyze the root causes of quality issues and improve the welding process continuously.

Roles in Production Management

Welding Production Management Through Welding Data Integration and Secondary Data Generation

Checking Amount of Real-Time Practice

- Checking Daily Welding Volume for Each Piece of Equipment

Checking Working Hours

- Checking welding time and welding rod consumption by day

- Checking the amount of practice by date, equipment, and trainee

Report Function

- Checking data separation by date and worker

- Automatic generation of daily, weekly, and monthly reports

Step 1: Monitoring the Real-Time Production Status and Equipment Operating Rate

- Function: The system displays the number of ongoing welding tasks and their progress in real time, allowing users to monitor the operational status (running/standby/stopped) and operating rate of each welding equipment.

- Operating method: The system automatically detects the start and end of welding work by monitoring current and voltage levels and updates production output in real time by counting the number of completed welding works. The system also determines the equipment operating status based on power on/off signals and generation of welding arcs.

- Contribution to production: The system enables managers to view production status at a glance, check the progress against production plans, and identify bottlenecks early to help operate production lines efficiently.

Step 2: Analyzing Worker and Equipment Efficiency

- Function: The system analyzes the production volume, working hours, and defect rates for each individual worker and statistically analyzes each welding equipment’s productivity, downtime, and defect occurrence frequency.

- Operating method: The system aggregates and analyzes data on the welding work performed by each worker based on registered workers and equipment information. For example, if a specific machine shows a high defect rate, the system can signal that it needs maintenance.

- Contribution to production:The system accurately identifies the **causes of a drop in productivity (e.g., inexperienced worker, outdated equipment)** and provides a concrete basis for decision making aimed at improving production efficiency, such as optimizing workforce allocation, assessing training needs, and establishing equipment maintenance plans.

Step 3: Analyzing and Optimizing Productivity Based on Production History Data

- Function: The system analyzes production trends, time required for each process, and causes of downtime in depth by evaluating a large volume of accumulated production history data and identifies optimization measures to improve productivity.

- Operating method: Based on data, the system visualizes the monthly and quarterly production volume trends, lead times for specific products, and key causes of downtime (material shortages, equipment failures, and worker breaks). This enables managers to plan future production schedules and identify opportunities to improve inefficiencies in specific processes based on historical data.

- Contribution to production: The system eliminates waste and improves production processes to maximize the overall operational efficiency. This leads to cost savings and on-time delivery, ultimately enhancing the company’s competitiveness.

Step 4: Managing the Use of Consumables (Welding Rods, Gas, etc.) and Optimizing Inventory (Optional)

- Function: The system estimates the consumption of welding rods, shielding gas, and other consumables to manage inventory levels and send order notifications automatically when stock shortages are expected.

- Operating method: Based on data such as wire feed speed and gas flow rate, the system calculates the use of each consumable and compares it to a preset inventory reference point. If stock levels fall below the critical point, the system notifies the manager.

- Contribution to production: The system prevents production downtime caused by consumable shortages and minimizes unnecessary inventory costs, thereby improving the stability and efficiency of your production plans.

![[en] Check plus](https://www.check-plus.co.kr/en/wp-content/uploads/sites/2/thegem-logos/logo_d3e2b261d6c769107c9b2f98f9000ff0_1x.png)

![[en] Check plus](https://www.check-plus.co.kr/en/wp-content/uploads/sites/2/thegem-logos/logo_116c52c5bc4d9aeff9a4f0cfad2da94c_1x.png)

![[en] Check plus](https://www.check-plus.co.kr/en/wp-content/uploads/sites/2/thegem-logos/logo_c8cf7336dc8a50da5992bd91a0dac7d3_1x.png)

![[en] Check plus](https://www.check-plus.co.kr/en/wp-content/uploads/sites/2/thegem-logos/logo_940a6b60336709fe0095ac2b1f39b2da_1x.png)